Corrugated Cardboard Automatic Folder Gluer Carton Box Make Machine

Function of carton box folding gluing machine each unit:

1.Feeding part

1.1Adopt adsorption type belt lead edge paper feeding method,accurately and stable.

1.2Adopt high-grade electromagnetic clutch and electromagnetic brake system.Paper feeding unit can be controlled individually.Easy operation.

1.3Creasing wheel is adjustable for the thickness 2-8mm of cardboard.

1.4Frequency control of motor speed with the glue folding unit,has a speed of 0-130m/min.

1.5Front baffle and the belts of the feeding unit can bu adjusted right and left,quick adjustment of various size and length of the cardboard box.

2.Glue folding part

2.1Main motor adopt frequency control of motor,no noise,convenient and stable.

2.2Imported circular seamless docking convey belt made of high wear resistant materials,folding of cardboard accurately and automaticly.

2.3Gluing unit selects high quality stainless steel gluing wheels,coating evently,trouble free and glue saving.

2.4Folding unit equipped with paper corrective and creasing corrective device.

2.5Folding speed 0-130m/min.

2.6Folding unit equipped with two rows fixed position wheel,precision shaping.

2.7The right and left baffles are adjusted electrically.

3.Counting and stacking part

3.1With PLC programmable controller and touch screen digital control,easy operation,input date without downtime,auto counting,stacking and output.

3.2Counting unit adopt frequency control,speed can be adjusted.

3.3With imported circular seamless docking convey belt,stacking trimly,has a speed of 0-130m/min.

3.4Counting and output pneumatically,with PLC,accuracy and fast.

3.5Output unit adopt upper and lower belt compressing tightly,make the carton gluing firmly and output trimly.

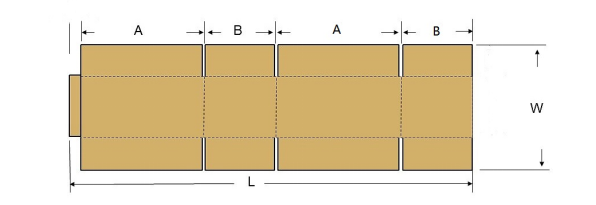

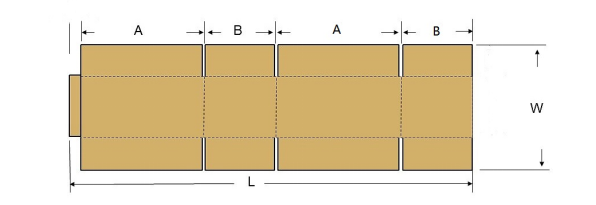

Model | QZD 2200 |

Size of A | 80-880mm |

Size of B | 160-840mm |

Size of W | 250-1100mm |

Size of L | 700-2200mm |

Install area | 3500*14000mm |

Motor power | 10 KW |

About us:

NORTH PACK company is a comprehensive company integrating design, R & D, production, sales and service. Our mainly produces corrugated board production line, high-definition high-speed flexo printing machine, automatic carton gluing and stitching machine ,and other corrugated packaging machinery.

NORTH PACK company's products have passed the technical qualification certification, and are exported to more than 70 countries and regions such as Southeast Asia, Eastern Europe and South America. NORTH PACK will always be your trustworthy friend.

Exhibitions:

Our company has actively participated in various domestic and foreign exhibitions in Shanghai, Turkey, Egypt, India and other countries and regions to show our products and services.

Our Services

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

PS: Normally our machines are uneasy to broken because of our professional machine making team and strict QC team, we will also send you our manual and video, what you need to do is just learn some basic thing such as machine maintenance.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. Where is your factory located ? How can I visit there?

Our factory located in Dongguang County, Hebei Province, China., near to the

capital city Beijing and port Tianjin. You can fly to Beijing airport directly and we

will pick you up there.

4. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling from the very small thing(even a small screw we will choose the best quality) from the beginning.