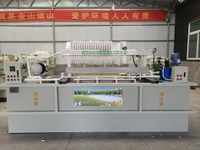

North Pack Lead Edge Flexo Printer Computer Slotter Die Cutter Machine

Machine performance:

1, Human-machine interface, full touch screen operation. Computerized control can store commonly used orders, faster order change and more convenient operation.

2, All electrical and electronic components are made of international famous brands

3, All transmission rollers are high quality steel, hard chrome plated and surface grinding.

4, Wall plate is 50 thick high quality cast iron, after de-internal stress treatment and then processed by CNC machining center.

5, Painting process: the parts are de-rusted-phosphatized-painted-baked before painting, which can make the paint play the role of anti-rust, hard surface, and the paint is more durable.

5, The whole machine is attached with alarm bell; the bell is continuously rung for warning when walking to ensure the safety of operators.

7, Emergency stop switch is set in each unit, which can stop the movement of each unit from inside to ensure the safety of internal operators.

8, Spray lubrication dual oil pump automatic circulation system to maintain oil level balance.

9, The number of orders can be stored in the computer control system can reach 999

Main technical parameters:

Equipment Name | lead edge 4 color printer slotter die cutter |

Wallboard width | 2800mm |

Design speed | 150 sheets/min |

Economic speed | 120 sheets/min |

Wallboard thickness | 50mm |

Gear thickness | 50mm |

Maximum feeding size | 1200*2600mm |

Minimum feeding size | 300*650mm |

Maximum print area | 1200*2500mm |

Standard print plate thickness | 7.2mm |

Applied cardboard thickness | 2-12mm |

Printing register accuracy | ±0.5mm |

Slotting depth | 300mm |

Slotting and die-cutting accuracy | ±1mm |

Working rate | 22kw |

Voltage | 380V |

Machine size | 8000*5000*2500mm(L*W*H) |

Sample for reference:

NORTH PACK the flexo printing machine for the corrugated cardboard carton box make, there can choose single color,,double color, three color, four color and so on, According to different needs can be customized for customers.

Packaging & Shipping

After the machine is finished and running well, it will be coated with anti-rust oil, which makes the machine not easy to rust in the container, and winding film to prevent moisture. Each unit of the machine will be fixed in the container to ensure a stable and safe arrival at the destination.

About us:

NORTH PACK company is a comprehensive company integrating design, R & D, production, sales and service. Our mainly produces corrugated board production line, high-definition high-speed flexo printing machine, automatic carton gluing and stitching machine ,and other corrugated packaging machinery.

NORTH PACK company's products have passed the technical qualification certification, and are exported to more than 70 countries and regions such as Southeast Asia, Eastern Europe and South America. NORTH PACK will always be your trustworthy friend.

Exhibitions:

Our company has actively participated in various domestic and foreign exhibitions in Shanghai, Turkey, Egypt, India and other countries and regions to show our products and services.

Our Services

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

PS: Normally our machines are uneasy to broken because of our professional machine making team and strict QC team, we will also send you our manual and video, what you need to do is just learn some basic thing such as machine maintenance.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. Where is your factory located ? How can I visit there?

Our factory located in Dongguang County, Hebei Province, China., near to the

capital city Beijing and port Tianjin. You can fly to Beijing airport directly and we

will pick you up there.

4. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling from the very small thing(even a small screw we will choose the best quality) from the beginning.

Display of related machines: