FUNCTION,CHARACTERISTICS AND CONFIGURATION:

Servo printing fold gluing bundling linkage line achieve CNC computer numerical control linkage operating system,each unit servo dribe independetly,accurate synchronization effect,speed is stable and reliable;Ossess the order management function;Accomplish the carton printing,fold gluing,bundling in line with high efficiency production.Design concept according to advanced European technology,and through the European CE Ceritification,is the best choice for inproving the production efficiency,reducing the manpower cost,automated corrugated box production,printing and forming process.

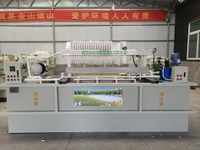

Automatic Bottom Folding Gluing Machine

Automatic down-side folding and gluing , attached and Synchronized with automatic printing die-cutting machine and automatic bundling machine. High speed and efficiency.

Automatic down-side folding and gluing , attached and Synchronized with automatic printing die-cutting machine and automatic bundling machine. High speed and efficiency. Can save 7-8 labors and save the factory space. Easily achieve per hour produce 10000 ready cartons.

Machine consists of three part which is board feeding part , gluing & folding part and counting stacking part . Speed adjustment can be done by touch screen and remote.

It adopt 4 times of scoring and correction parts to make sure paper feeding high accuracy.

Machine is frequency conversion control, with imported drive. Touch screen display the running data and can do order change easily from touch screen. After input new order size, machine can automatically change into needed position , highly increased working efficiency. Different size of carton , quick and convenient to adjust.

Whole machine is heavy duty with high quality bearings, imported electrics, thickness pipes, imported belts.

1. Main components:

1. Lead-edge feeding part one unit

2. Printing part four unit

3.Slotter part one unit

3. Die-cutting part one unit

4. Automatic gluing part one unit

5. Bundling part one unit Totally 9 units.

2. Main parameter

| Model | GYSM1450X2800 |

| Max. speed | 200pieces/min |

| Economic working speed | 180 pieces/min |

| Minimum sheet feeding size (mm) | 380*650 |

| Maximum sheet size for continuous feeding(mm): | 1400*2800 |

| Maximum sheet size for skip feeding (mm): | 1400*2800 |

| Maximum printing area (mm): | 1400*2600 |

| Minimum slotting space (mm): | Positive blade: 280*70*280*70

Negative blade:

180*180*180*180 |

| Maximum slotting depth (mm): | 320 |

Range of printing plate thickness(mm):

| 4.5-7.2

Standard thickness:6 |